BMS Bench Testing

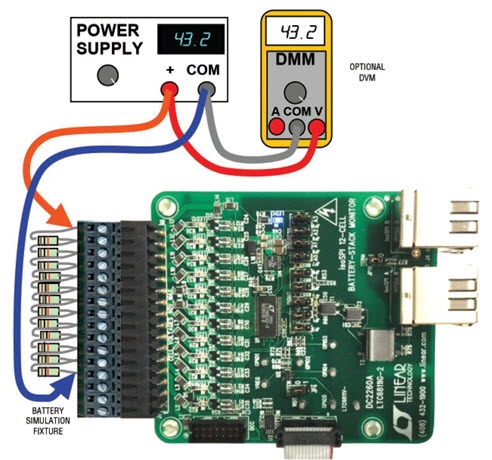

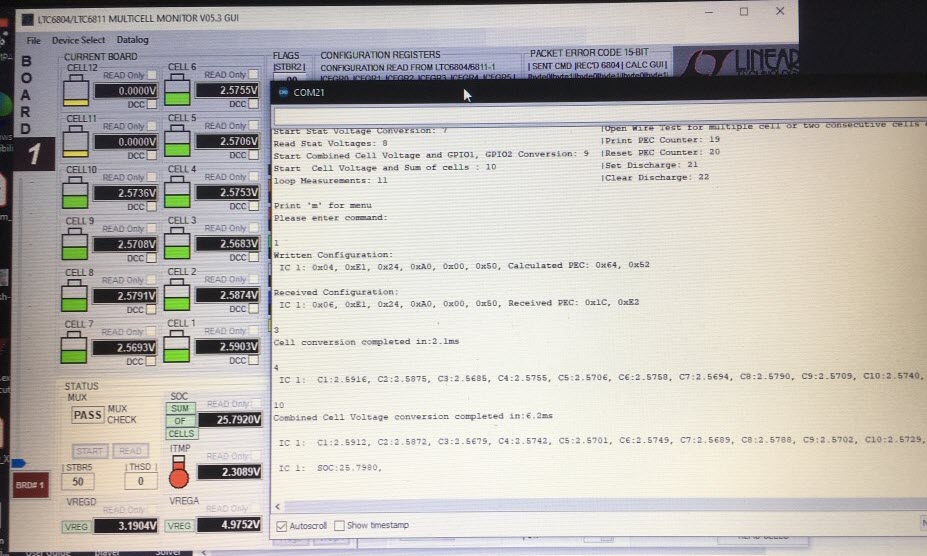

As I complete the build of each BMS PCA I have been bench testing them. When I first got the Chevy Bolt batteries and purchased the BMS demo boards, I built a resister ladder board using barrier strips and through-hole resistors. The test method was detailed in the manual for the BMS demo and is shown in the first image below. But instead of connecting resistors directly to the DC2260A BMS demo I have 10 resistors wired in series on the barrier strip to mimic the battery cells and a power supply that supplies a voltage similar to the battery stack voltage. All the resistors are the same, so nearly the same voltage drop occurs at each resistor, when a voltage is applied to the series. For my resistor series a wire is connected to each resistor and then soldered to a DB25 connector. I made this system to learn how to use the DC2260A BMS demo boards and the software when I got them two years ago. The resistor ladder is much easier to use than a battery for testing BMS boards and safer. The resistors are basically a current limiter and the power supply used to power the resistor series is current limited, so if anything shorts out it should not be catastrophic like it would be using a battery with all the current capacity. I added another set of wires and DB25 connector in parallel to the first set of wires so I could measure my BMS board and the DC2260A demo board simultaneously to compare the voltages measured. The setup is shown below and a screen capture of the simultaneous testing. As described in the Blog below (BMS Update) I have found my demo boards have an average offset of 400 microvolts from the DC2260A BMS demo board. That offset has been the same for every board I have assembled and it is the same value as the noise measured on all of the readings of +/- 0.0002V. I don’t really care about that offset, however, because I am only going to use my BMS boards as a battery monitor. The voltage readings are very reproducible and that is all that matters. Once I finish building all the BMS boards I will need to flux clean them and then conformal coat the PCAs. I will need to retest everything after those operations. Then I will ready to deploy the system in my car.