Bolt Batteries Update

I have a video I have mostly put together but have not posted, on an issue I found with the Chevy Bolt batteries. I found it when using the Analog Devices DC2260A demo BMS board to understand more about the Bolt batteries (see Blog Chevy Bolt Batteries). Once I understood how to connect the demo BMS to the battery modules I used it to test all 9 battery modules that I had purchased. All 90 cells in the batteries were nearly the same voltage, +/- 2.5mV, but I found one battery that seemed like one of the cells was not connected. The BMS demo software showed two issues. First one of the cells would read lower voltage, second, the adjacent cell would read a higher voltage than any of the other cells. This difference was highlighted when the discharge circuit was activated in the BMS. The lower voltage cell would read nearly zero volts and the adjacent cell would read 5.46V which is clearly not possible. I believed that is just an issue with the A/D converter circuit in the BMS Integrated Circuit on the demo board and it is not reading that voltage on the cell. Analog Devices tech support said it was due to the Transistor (MOSFET) in the balancing circuit turning on full because of an open circuit. After some investigation I discovered that two connections to the battery cells were open, i.e., disconnected. On the Chevy Bolt battery module all the cells are connected to the BMS connectors on the front of the battery by two narrow PCAs that run the length of each side of the battery module (see image below). I believe what has happened is that traces on the PCAs are broken somewhere causing the open circuits. It might be where the cell is soldered to the PCA (yellow arrow in image below) although there is no visible indication of an open circuit anywhere. I solved the measurement problem by soldering wires directly to the cell solder points and bringing the wires out to the DB25 connector. What is disturbing is that this particular battery was never installed in the car. I needed to have the front battery box in my car modified to fit the 9th battery module, so I had that battery on the bench, ever since the time I received it. It was essentially delivered with that open circuit. This was discovered in December of 2020, shortly after I had received the batteries and got the demo BMS connected to the batteries. Eight of the Chevy Bolt batteries have been in the car since then and been subjected to many charge/discharge cycles, while driving the car for the past 3 years. I had used the Chevy Bolt wiring harness to make connections to all the batteries (again see Blog Chevy Bolt Batteries) so that I could connect the demo BMS to every battery and measure the cells, one battery module at a time. That is why I decided to make my own BMS, so that a BMS circuit could be connected to each battery module all the time and allow constant monitoring. Since I have been monitoring all the battery cells, I have found that 6 out of the 9 batteries received now have one or more cells that measure open, with the BMS. The other batteries developed the open cells sometime over the past 3 years, but I believe this highlights the defect that was in the LG Chem batteries that caused the battery fires seen in some of the early Chevy Bolt EVs. As a human reviewing these results, I could understand the problem with the batteries, that it is just a measurement problem. But the firmware in the Chevy Bolt BMS might not identify that problem, it there was no code to look for it. If a similar A/D converter circuit was used in the Bolt BMS and the firmware was not programmed for this problem you can image what might happen. The way a BMS typically maintains battery cells is to move charge between the cells to balance the voltage. If the BMS did not know about the open cell voltage measurement, then it might move current out of the false high voltage cell and push it into the false zero voltage cell. Over several charge cycles this could develop into real problem where the false zero voltage cell was getting overcharged and the false high voltage cell could be over discharged. Both of these scenarios could cause a battery fire because both cells would still be charged when the full pack was charged. The cell maintenance is very small amount of current but could eventually damage cells. If this was happening in over half of the battery modules in the Chevy Bolt is a wonder not more fires occurred. This is a manufacturing defect (broken PCA traces) but also a firmware issue in the BMS. The broken traces in themselves do not affect the performance of the battery module and would never lead to a fire. It is only the action of a BMS Firmware that was not programmed for this defect could cause that. LG Chem only admitted that a manufacturing defect caused the files, but said nothing about the BMS. The BMS being the cause is also the opinion of a number of automotive journalists. This issue with the open cells measurements highlights why my BMS is a Battery Monitoring System and does no cell maintenance. Three years of testing the battery modules in the car show a very narrow cell voltage distribution without doing any cell maintenance. This is an indication of how well the cells in the battery module were manufactured. It is too bad the open circuit cell voltage measurement was not identified early in the Chevy Bolt EV development. The battery fires may never have happened and the Bolt EV would still be sold by Chevy after 2023.

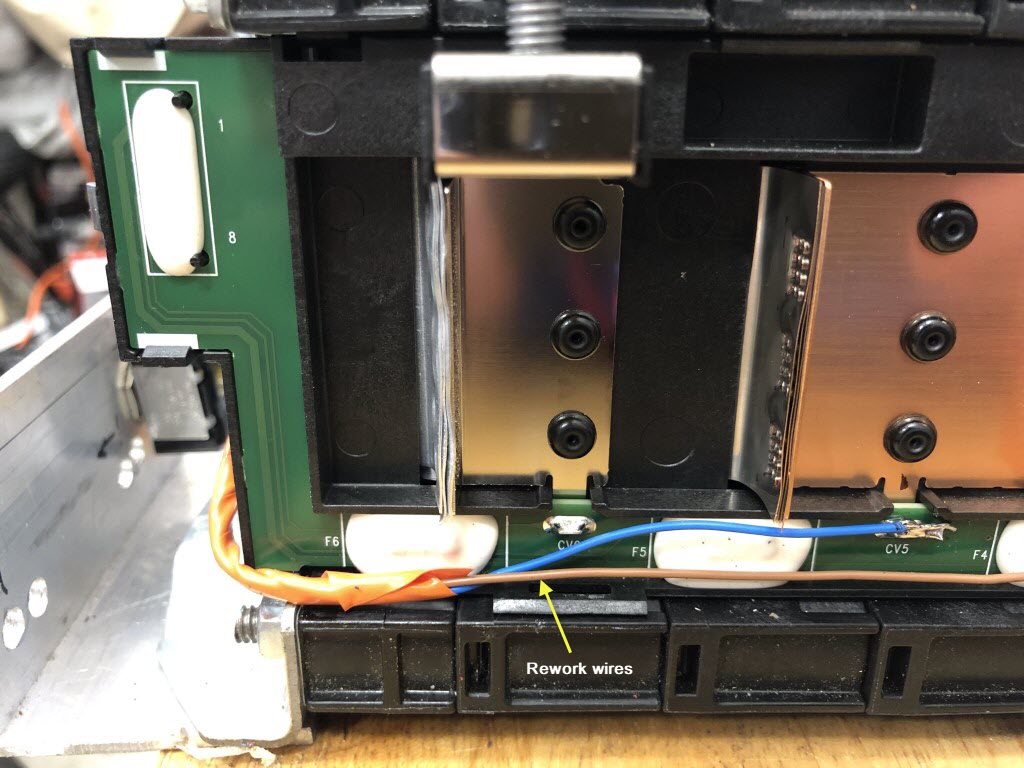

Shown below is the rework to fix the BMS circuit. The second wire goes to the 4th cell. There is another wire on the opposite side that connects to cell 5. Usually two wires are required to fix a channel in the BMS circuit.

A video of the Chevy Bolt battery is coming soon.