320i Specs and EV Design

This 320i in fantastic condition was found on Ebay. The car had been stored for more than 15 years which is why it is in such good condition. It has many features that make it any ideal doner car for an electric vehicle conversion. First, it is very light, about 2500 lbs curb weight. Second, it has lots of room for placing batteries. Third, it basically has no computer systems for controlling the car. This BMW 320i is actually a 320i"s" for sport version. It has an upgraded suspension, a limited slip differential and the seats in the passenger compartment are "Recaro" seats - very tight bucket seat. Here is the link on Wikipedia for the 320 series.

Proform Vehicle Scale weight distribution after ICE component removal:

Left front = 403 lbs; Right front = 363 lbs Total = 766 lbs

Left rear = 509 lbs; Right rear = 502 lbs Total = 1011 lbs

Total weight = 1776 lbs, so based on a curb weight of 2452 lbs that means 675 lbs for the ICE components. Probably not all that weight just off the front end. Some weight was for the gas tanks and exhaust and drive shaft.

Battery placement

18 cells in front between wheel wells = 80 lbs

Siemens motor and DMOC 645 = 320 lbs

48 cells under rear seat = 213 lbs

54 cells in trunk, over the rear axle = 240 lbs

Brusa charger in trunk = 13 lbs

Front added weight = 80 + 320 = 400 lbs

Rear added weight = 213 + 240 + 13 = 466 lbs

Front will also have water heating and cooling, brake vacuum and DC-DC converters, that will be at least 60 lbs and some of the battery weight under the rear seat will probably translate to the front wheels.

Just the batteries and motor and components weight added to the de-ICE weight gives 2642 lbs. The transmission, clutch and drive shaft weigh 108 lbs. Of course the battery boxes will add weight. The total conversion weight still should be well under 3000 lbs.

Post build note: weight is 2860 lbs with a 48/52 front/rear weight ratio.

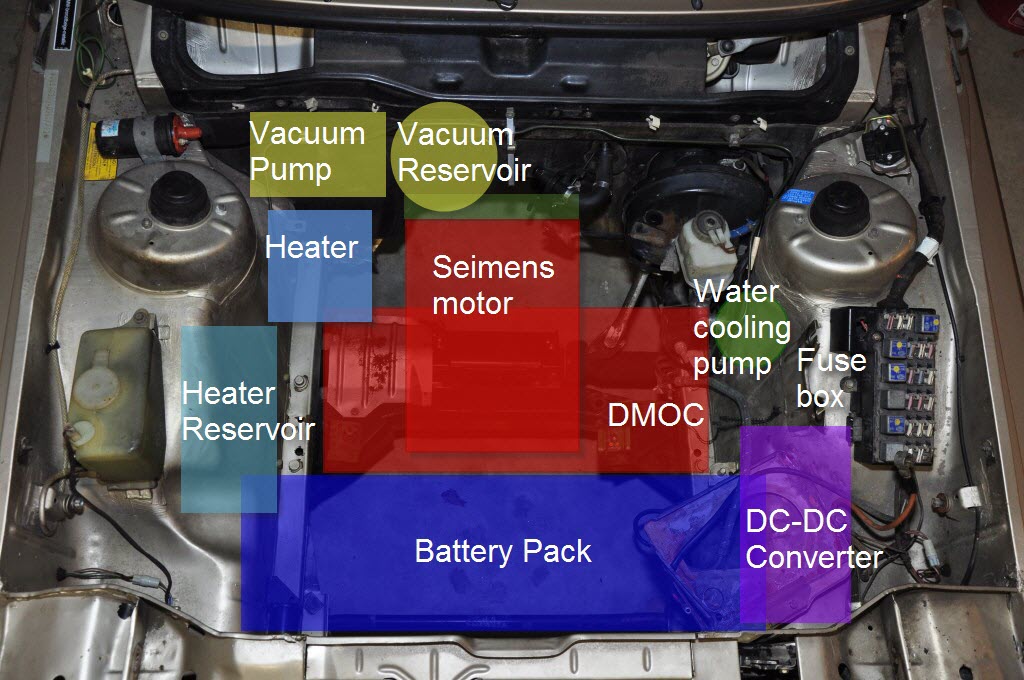

Here is the design layout of most of the components for the engine compartment.

On an EV electric motors have to provide resources like heating and vacuum that were available on the ICE. So there is a vacuum pump and reservoir for the brakes and cabin controls and a heating unit and reservoir for the fluid to heat the cabin. The Siemens drive motor does not need much cooling, but the DMOC inverter does need to be cooled. So there is a pump and heat exchanger. The heat exchanger is a small radiator and it will sit directly behind the front grill. The radiator needs a fan for when the vehicle is not moving. The 320i has a fan that was intended to cool the evaporator coil for the air conditioning, even though there is no air conditioning on the car. But I found that the fan draws 25 Amps! A heat exchanger from Derale will be used instead. It only draws 5 to 6 Amps.

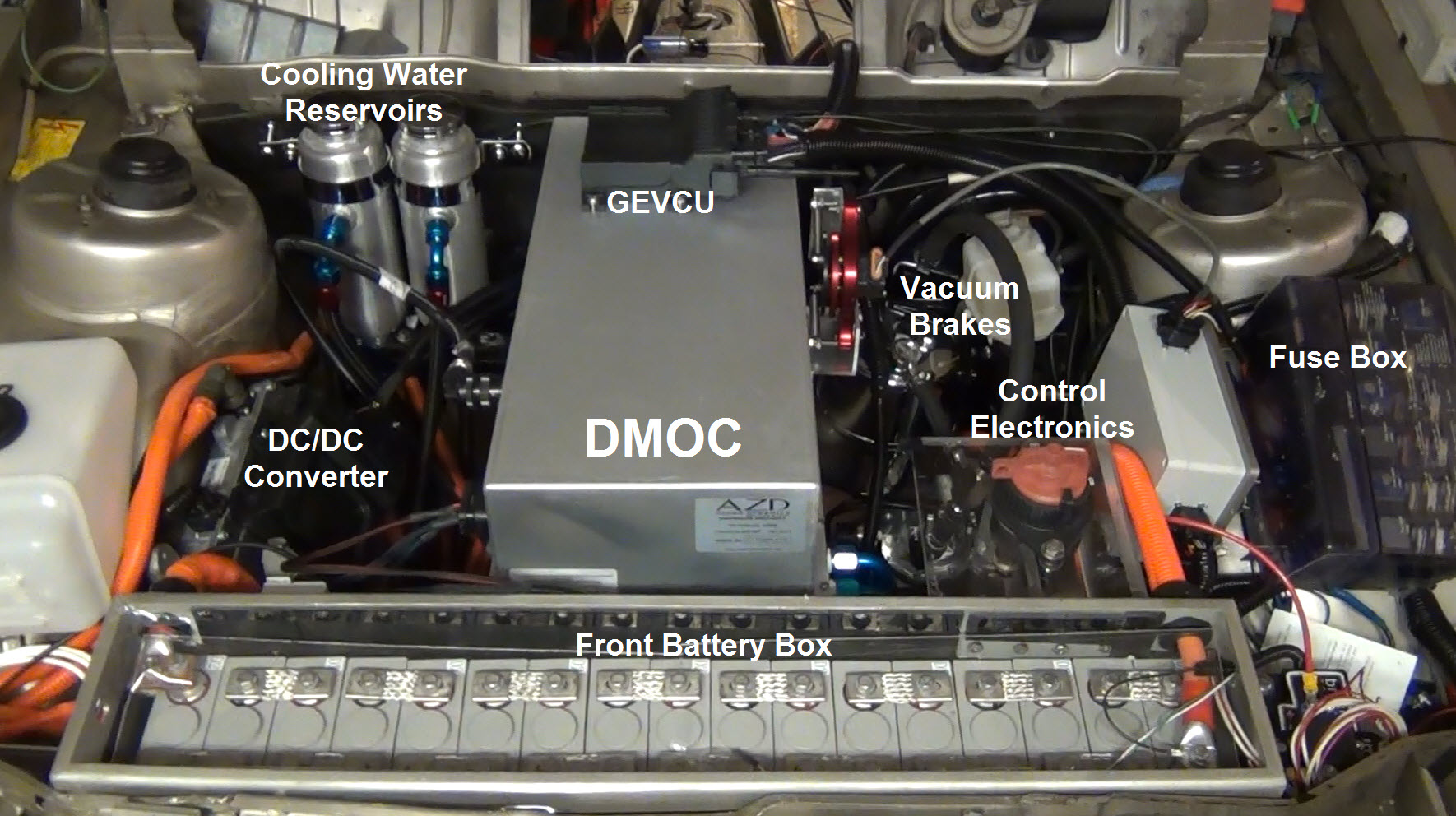

Below is how the actual build looks like. The Siemens motor is below the DMOC so it cannot be seen. Water pumps are also below as well as the main contactor box. There is no heating reservoir as I am using PTC heater elements to heat the passenger compartment.

Below is the latest upgrade. The DMOC and GEVCU were replaced with a Scott Drive controller system. The Control Electronics have also been removed as all that functionality is contained in the Scott Drive.

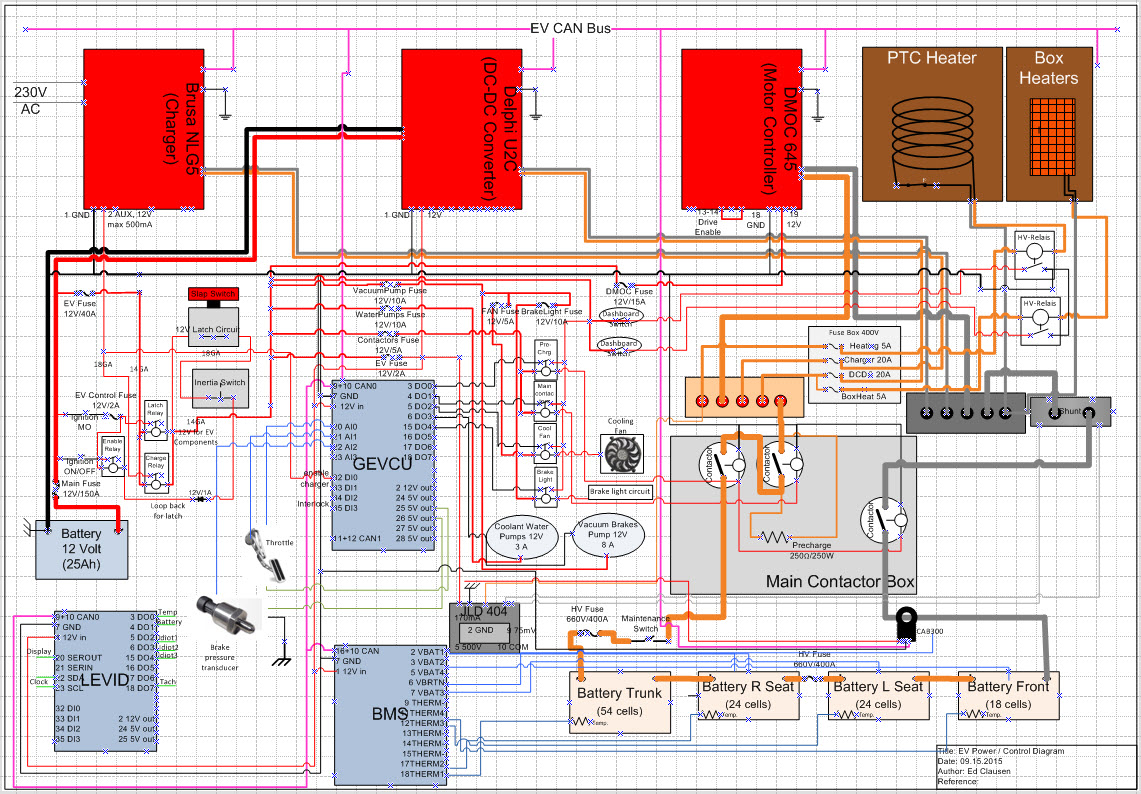

Below is the wiring schematic for the complete design. A larger view of this diagram can be seen in the photogallery.

I plan to use the 5-speed manual transmission from the 320i for the EV build. That will be used with a racing clutch from Summit Racing. A high torque clutch is required because of all the torque the electric motor generates at zero RPM. If the clutch is not strong enough the vehicle might not even move and the clutch will just spin and burn. The clutch and flywheel will be spin balanced together. That is done to reduce drivetrain vibrations which are very noticeable in a electric drive vehicle because the motor does not vibrate like an ICE. The balancing is being done by a local company called Lindskog Balancing. The 5-speed transmission will be coupled to the Siemens motor using a bell housing adpater made by RebirthAuto and a spline adapter made by EV West shown below. The adapter connects the spline drive shaft of the electic motor to the flywheel, clutch and transmission. The clutch side is shown.

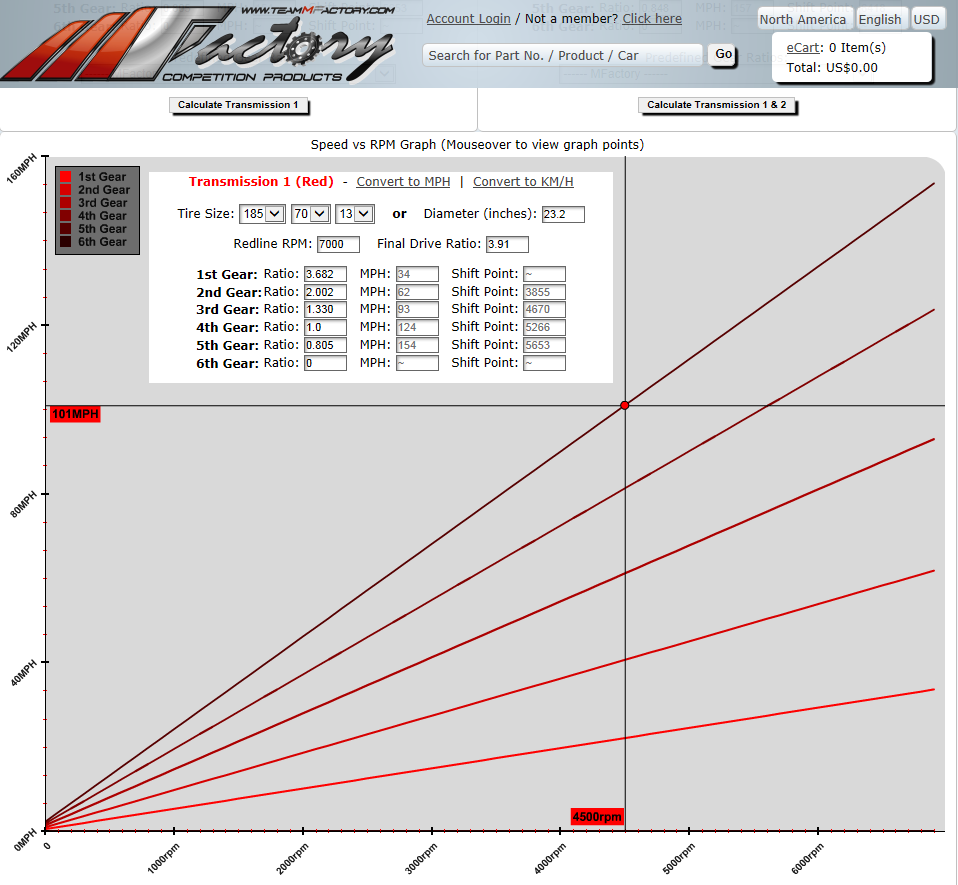

On the 2/7/2014 issue of the Vblog at EVTV there was a discussion of gear ratios, RPM and speed. Below is a graph of the calculated speed as a function of RPM for the 320i with the current gear ratios and tires. It shows that at 4500 RPM in 5th gear the 320i should be capable of over 100 MPH. This graph is from TeammFactory.com